MAGnetometers for Innovation and Capability

... it's like magic (but it's science)

With the technical know-how lost to history and stockpiles dwindling, the University of Iowa is rediscovering and advancing the nation’s ability to make the high-fidelity magnetic field measurements needed for space science and space weather missions.

Background

Fluxgate magnetometers provide high-fidelity measurements of the local magnetic field, though their performance is limited by the magnetic noise of a specialized ferromagnetic 'core'. Many of the best fluxgates worldwide use what are known as S1000 cores that were developed in the 1960s and have been out of production since 1996. These cores were produced using 6-81 Permalloy (6% Molybdenum, 81.3% Nickel, remainder Iron). Incredibly, the manufacturing process to create these high performing cores is lost to history. With the stockpiles dwindling, many researchers are going to great lengths to recycle S1000 cores from previously made fluxgate magnetometers. This is clearly unsustainable.

Looking Forward

To enable a new generation of magnetic field instruments for future scientific and operational missions, the University of Iowa is resurrecting and refining fluxgate technology to produce new high-quality cores. Along with national and international partners, the MAGIC team has demonstrated a manufacturing process that meets the noise performance of most cores in use today. Further, the team has revealed potential optimizations that could enable lower noise sensors, miniature sensors for nanosatellites, and efficient high-volume production for constellation missions.

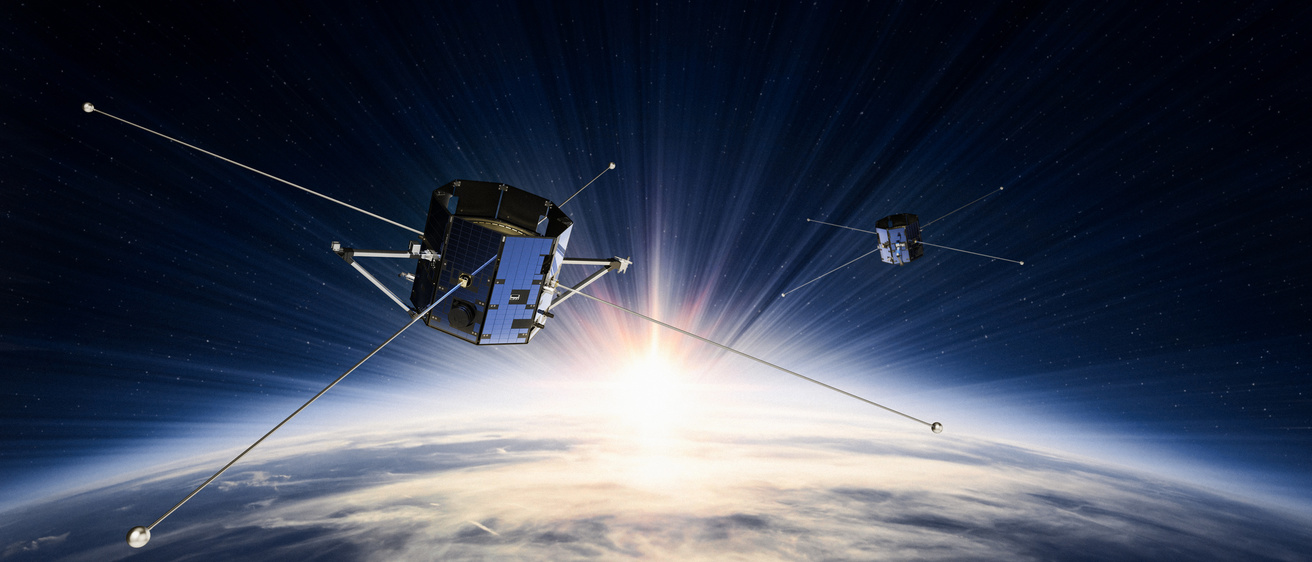

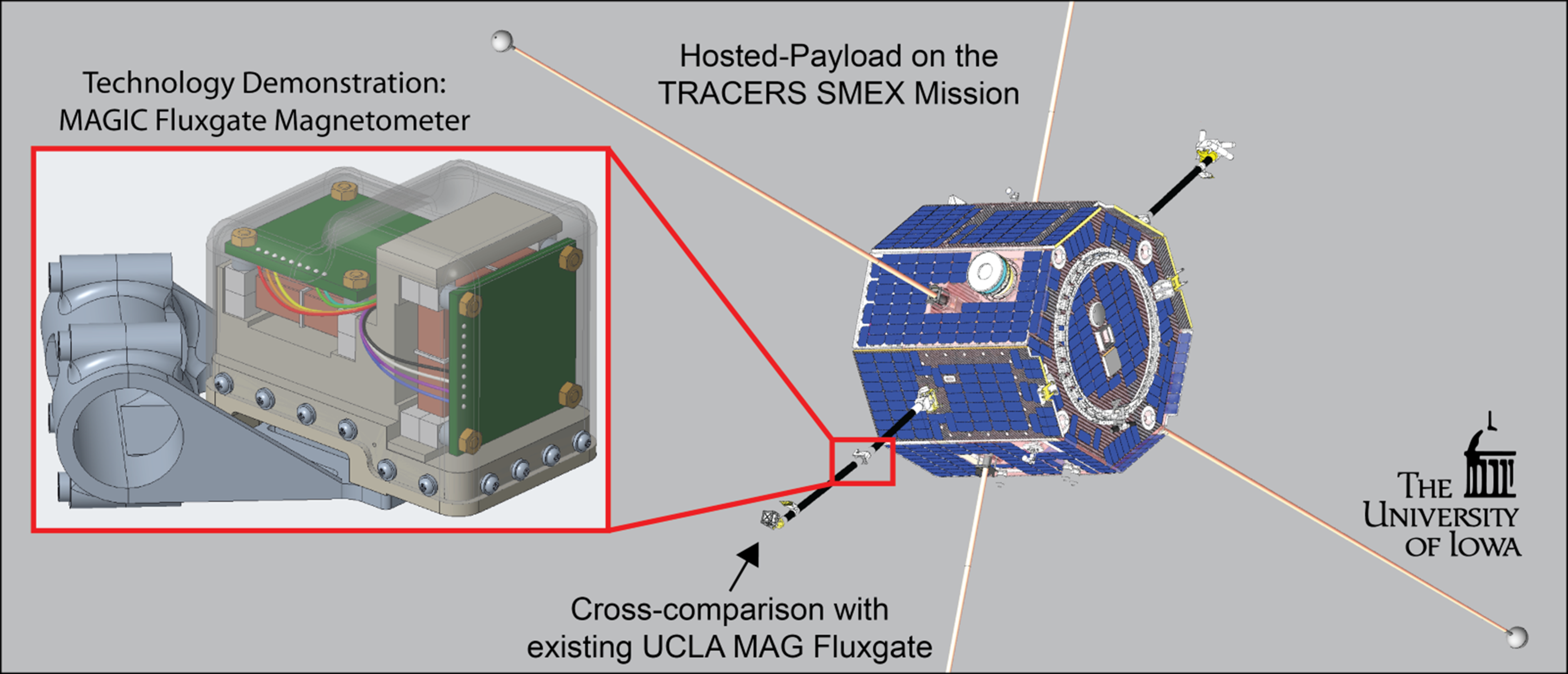

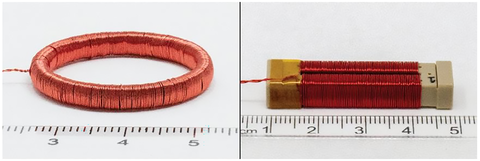

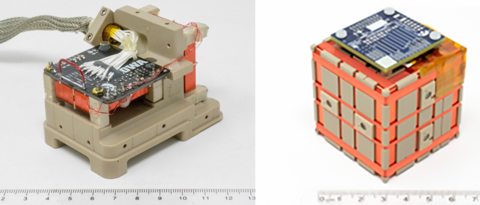

The MAGIC team will prove flight-heritage through a do-no-harm Technical Demonstration as a hosted payload on the TRACERS SMEX mission (i.e. the MAGIC instrument is riding along on TRACERS to show it can survive liftoff and operate in orbit without impacting the other instruments). This allows the team to test two designs, one on each spacecraft. T1, the leading TRACERS satellite, will host a MAGIC instrument with a 'Tesseract' sensor design and T2 will host a MAGIC instrument with a more traditional 'ringcore' sensor design.

The ongoing availability of high-quality magnetic field instruments is essential to investigations under the NASA Heliophysics overarching science goal to “Advance our understanding of the connections between the sun, Earth, the planetary space environments, and the outer reaches of our solar system” and the 2019 National Space Weather Strategy and Action Plan Objective 2.4 to “Identify, develop, and test innovative approaches to enable enhanced, more informative, robust, and cost-effective measurements. … This action should include … the development of novel observational approaches …”. MAGIC is aligned with the NASA Technology Roadmap and will help achieve TA 8.3.1.3 “Constellation Magnetometer” enabling missions of 10s to 100s of spacecraft each carrying a magnetometer to characterize the global morphology of the magnetosphere.

Making MAGIC

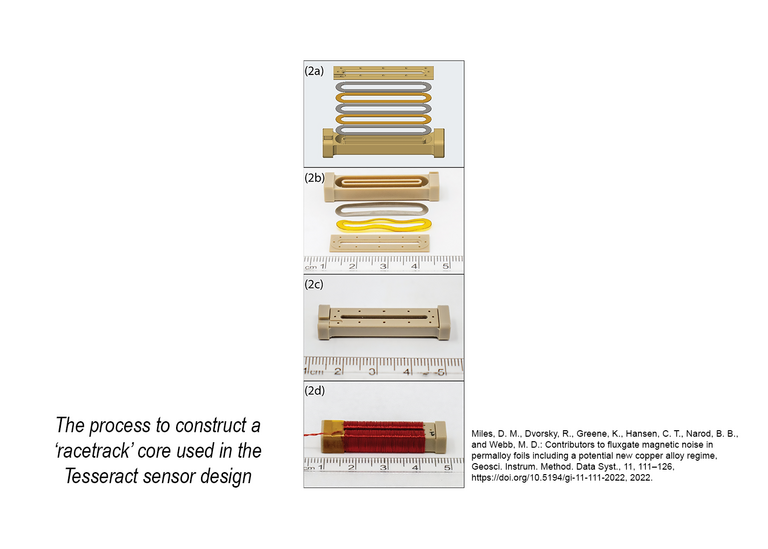

The University of Iowa team does not rely on legacy processes or materials. Rather, the new fluxgate cores are manufactured from scratch and integrated into a modern spaceflight magnetometer design. The ferromagnetic cores are produced starting from base metal powders that are melted into custom alloys in-house, cold-rolled into thin foils, formed into the geometry of a fluxgate core, and undergo multi-step heat treatments to optimize their magnetic properties. The resulting cores are integrated into a complete fluxgate sensor ready for a spaceflight application.

Because the MAGIC team designs, prototypes, and manufactures the cores, sensors, and paired electronics in-house the team can explore various designs while also reverse-engineering and enhancing the traditional ringcore design.

High-stability 'Tesseract' sensor (T1)

Traditional 'ringcore' sensor (T2)